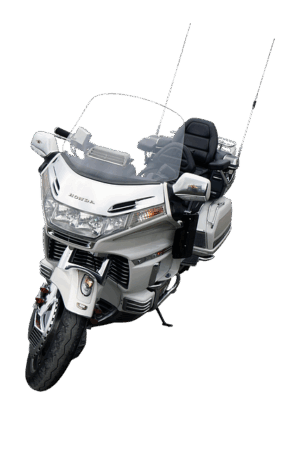

Discover Honda Shepparton: Your Local Bike Haven at 182 Numurkah Road

Honda Shepparton, located at 182 Numurkah Road VIC, is a premier destination for motorcycle and scooter enthusiasts. It offers a comprehensive range of Honda motorcycles and scooters, expert advice, and exceptional service. Power N Play, also si…….